Introduction to Magnetic Assemblies and Precast Concrete Shuttering Magnets;

When it comes to construction and manufacturing, the tools and materials you choose can make or break your project. Two popular options on the market today are Halbach Array magnetic assemblies and precast concrete shuttering magnets. While both serve a critical purpose in shaping concrete structures, they come with unique features that set them apart.

Have you ever wondered how these innovative solutions stack up against each other? Whether you’re looking for something that offers superior strength or ease of use, understanding their differences is key to making an informed decision. Let’s dive into what each option brings to the table so you can determine which is right for your specific needs.

What Are Halbach Array Magnetic Assemblies?

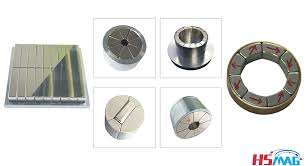

Halbach Array Magnetic Assemblies are a fascinating technology in the world of magnetics. They consist of an arrangement of permanent magnets that optimize magnetic fields on one side while canceling them out on the other. This unique configuration maximizes the strength and efficiency, making these assemblies particularly effective for various applications.

– Explanation of the Halbach Array design

The Halbach Array is a clever arrangement of magnets that enhances magnetic fields on one side while canceling them out on the other. This unique design consists of alternating magnet orientations, creating a powerful magnetic effect where it’s needed most.

At its core, the array maximizes efficiency. The layout allows for stronger attraction and repulsion without increasing the size or weight of the assembly.This innovative approach has transformed various applications, from motors to sensors, by providing effective solutions in compact spaces. Many engineers favor this design because it minimizes wasted energy and optimizes performance.

In construction and manufacturing settings, Halbach Arrays can be particularly beneficial. They provide reliable holding power with minimal space requirements, making them an attractive option for modern projects looking to leverage advanced technology.

– Advantages of using Halbach Array assemblies

Halbach Array assemblies stand out for their remarkable efficiency. By cleverly arranging magnets, they create a stronger magnetic field on one side while canceling it on the other. This design maximizes holding power where needed most.Another advantage is versatility. These assemblies can be tailored to fit various applications, from automotive components to industrial machinery. Their adaptability ensures that you get precisely what your project requires.

Additionally, Halbach Arrays are lightweight yet robust. They enhance performance without adding unnecessary weight, making them ideal for projects where every ounce counts.Their durability also deserves mention. Built with high-quality materials, these assemblies resist wear and tear over time, minimizing replacement costs and downtime in operations.

Moreover, installation is straightforward due to their user-friendly nature. This ease of use translates into quicker setup times and increased productivity right from the start.

What are Precast Concrete Shuttering Magnets?

Precast concrete shuttering magnets are essential tools in modern construction. They simplify the process of forming and shaping concrete structures. These magnets adhere firmly to metal formwork, ensuring that sections remain aligned during the pouring and setting stages.

The mechanism is straightforward. Each magnet generates a powerful holding force, keeping forms securely in place. This allows for a smoother workflow, reducing the risk of misalignment or shifting.One major advantage is their versatility. Whether it’s walls, slabs, or precast elements, these magnets cater to various applications with ease.

Additionally, they help increase efficiency on-site by minimizing setup times and labor costs. By using precast concrete shuttering magnets, construction teams can focus more on quality rather than struggling with traditional fastening methods.

– How they work

Precast concrete shuttering magnets are designed to facilitate the casting process in construction. They work by providing a reliable means of holding formwork in place, ensuring that concrete can be poured accurately and efficiently.

These magnets feature a strong magnetic force that securely attaches to steel surfaces or other ferromagnetic materials. When placed against the formwork, they create a tight seal, preventing any leakage during the pouring phase.Installation is quick and straightforward. Simply position the magnet where needed and let its grip do the rest. This eliminates cumbersome clamps or fasteners, speeding up project timelines significantly.

Once set, these magnets withstand high pressures from wet concrete without shifting or losing their hold. After curing is complete, removing them is just as easy—allowing for swift turnover between different casting jobs.

– Benefits of using precast concrete shuttering magnets

Precast concrete shuttering magnets offer a range of benefits that enhance efficiency in construction projects. Their primary advantage lies in their strong magnetic hold, ensuring that formwork stays securely in place during the pouring process. This minimizes the risk of leaks and misalignment.Another significant benefit is time savings. With quick setup and removal, crews can streamline workflows, allowing for faster project completion. This becomes crucial when meeting tight deadlines.

The durability of these magnets also contributes to long-term cost-effectiveness. Made from robust materials, they withstand repeated use without losing effectiveness or strength.Additionally, precast concrete shuttering magnets are lightweight and easy to handle. Workers can reposition them effortlessly as needed, reducing physical strain on the job site.

Their adaptability across various applications makes them suitable for diverse projects—from residential buildings to large commercial structures—ensuring versatility in every build.

Comparison between Halbach Array Magnetic Assemblies and Precast Concrete Shuttering Magnets;

When comparing Halbach Array Magnetic Assemblies to precast concrete shuttering magnets, several factors come into play.

Halbach Arrays excel in strength and holding power. Their unique design maximizes the magnetic field on one side while canceling it on the other, providing robust support for various applications.On the other hand, precast concrete shuttering magnets are designed for practical use in construction settings. They offer solid grip capabilities but may not match the sheer force of Halbach assemblies.

– Strength and holding power

When it comes to magnetic assemblies, strength and holding power are crucial factors. Halbach Array Magnetic Assemblies stand out due to their unique design. This arrangement enhances the magnetic field on one side while canceling it on the opposite side. As a result, they deliver superior holding capabilities compared to traditional magnets.

On the other hand, precast concrete shuttering magnets also provide reliable strength but in a different way. Their robust construction allows them to hold heavy formwork securely during pouring and curing processes. The pulling force is significant enough for various applications without compromising stability.

The choice between these two options often depends on project specifics. If precise alignment and strong bonding are essential, Halbach Arrays excel. However, if you need straightforward solutions for larger structures, precast concrete shuttering magnets can be more than adequate.

– Durability and longevity

Durability is a crucial factor when choosing between Halbach Array magnetic assemblies and precast concrete shuttering magnets. Each option has its strengths in this area.

Halbach Arrays are engineered for resilience. Their unique design allows them to maintain strength over time, even under demanding conditions. These magnets can withstand exposure to various environmental factors without significant loss of performance.On the other hand, precast concrete shuttering magnets also offer impressive durability. Made from robust materials, they resist wear and tear during repetitive use on construction sites. They handle heavy loads while maintaining structural integrity throughout numerous projects.Both options shine in terms of longevity but cater to different needs based on project requirements. The choice often depends on specific circumstances surrounding your project’s environment and intended application.

– Ease of use and installation

When it comes to ease of use and installation, Halbach Array magnetic assemblies shine. Their design allows for quick adjustments and repositioning. You can mount them in seconds, saving valuable time on the job site.

On the other hand, precast concrete shuttering magnets require a bit more effort during setup. While they do offer stability once installed, aligning and securing them can be a more cumbersome process. This might slow down your workflow if you’re working against tight deadlines.

Ease of removal is another key factor. Halbach arrays are simple to detach without damaging surfaces or materials. In contrast, removing shuttering magnets often involves additional considerations like surface integrity and potential wear.

Choosing between these options depends largely on your project needs. If speed and flexibility are priorities, Halbach assemblies may be the way to go. However, for projects requiring robust structural support over extended periods, precast concrete shuttering magnets have their merits too.

– Cost effectiveness

When considering cost effectiveness, both Halbach Array magnetic assemblies and precast concrete shuttering magnets bring unique advantages.

Halbach arrays often require a higher initial investment due to their advanced design and manufacturing processes. However, their superior holding power can reduce the number of units needed for a project. This efficiency may lead to long-term savings on materials and labor.

On the other hand, precast concrete shuttering magnets are generally more affordable upfront. Their straightforward installation process can also save time during construction, reducing labor costs significantly.Ultimately, weighing these factors against your project’s specific needs is essential. The choice between short-term expenses versus potential long-term savings will play a crucial role in your decision-making process when evaluating these magnet technologies.

Which option is right for your project?

Choosing between Halbach Array magnetic assemblies and precast concrete shuttering magnets hinges on several factors. When it comes to choosing the right magnetic solution for your project, there are two main options that often come into consideration: Halbach array magnetic assemblies and precast concrete shuttering magnets. While both of these options utilize magnetic force for various applications, they differ in their design, functionality, and suitability for different projects.

- Halbach array magnetic assemblies are a type of permanent magnet system that is commonly used for high-tech applications such as motors, generators, and speakers. They consist of an arrangement of multiple magnets on a cylindrical or rectangular core, with alternating poles facing in opposite directions. This unique configuration creates a strong and focused magnetic field on one side while minimizing the field on the other side. This makes Halbach arrays ideal for applications where a strong and directional magnetic force is required.

- On the other hand, precast concrete shuttering magnets are specifically designed for use in construction projects. They are made up of powerful neodymium magnets encased in steel casing with threaded holes or eyelets for easy attachment to formwork structures. These magnets provide a temporary but extremely strong holding force to secure formwork panels during concrete pouring. They eliminate the need for drilling or welding onto formwork structures, making them convenient and cost-effective solutions for repeated use.

- So which option is right for your project? The answer ultimately depends on your specific needs and requirements. If you require a strong and directed magnetic force for precision-based applications such as motor assembly or levitation systems, then Halbach array magnetic assemblies would be the better choice. However, if you’re working on construction projects that involve repetitive concrete casting processes, then precast concrete shuttering magnets would be more suitable.

- It’s also worth considering factors such as durability and longevity when making this decision. Halbach array magnetic assemblies have no moving parts which make them highly durable with minimal maintenance required. On the other hand, precast concrete shuttering magnets may experience wear over time due to exposure to harsh construction environments. However, they are designed for repeated use and can withstand a significant amount of pressure.

Both Halbach array magnetic assemblies and precast concrete shuttering magnets have their own unique strengths and applications. It’s important to carefully evaluate your project needs and consider factors such as strength, directionality, durability, and longevity before making a decision. Ultimately, choosing the right option will ensure optimal performance and efficiency for your project.

Conclusion:

Choosing between Halbach Array Magnetic Assemblies and Precast Concrete Shuttering Magnets for your project is a significant decision. Each option has distinct features that cater to different needs.

If you prioritize strong holding power and innovative design, Halbach Arrays might be the better fit. Their unique structure maximizes magnetic fields, making them effective in demanding applications. However, consider their installation process and whether it aligns with your project’s timeline.On the other hand, if you’re looking for simplicity and cost-effectiveness, precast concrete shuttering magnets offer reliable performance without complexity. They are designed for ease of use, allowing quick setups on construction sites.

Assessing your specific requirements—strength, durability, ease of installation, and budget—is crucial before making a final choice. Real-world examples can provide insight into how each solution performs under various conditions.