In the world of compact construction equipment, few machines are as iconic or as versatile as the small, agile loader often seen zipping around job sites and farms. Known for their ability to turn within their own footprint and navigate tight areas with ease, these machines are commonly referred to as a skid steer. The name might sound unusual at first, especially if you’re unfamiliar with the mechanics behind how these machines move. However, once you understand how they operate, the term makes perfect sense. Let’s explore the origins of this name and what sets these machines apart from others in the industry.

How These Machines Move

One of the defining features of this compact loader is its turning mechanism. Unlike a traditional vehicle that uses a steering wheel connected to pivoting front wheels, these machines steer by skidding. They accomplish this by independently controlling the wheels or tracks on either side. When the wheels on one side of the machine move faster—or in the opposite direction—compared to the other, the machine pivots. This results in a sharp turning radius, often allowing the machine to rotate in place.

This method of movement causes the tires or tracks to drag or “skid” across the ground, especially when turning on hard surfaces. It’s this unique method of steering that gave rise to the term. Rather than turning by angling wheels, the loader steers by adjusting the speed and direction of each side, relying on friction to complete the maneuver. The turning method is both simple and effective, especially in confined spaces where traditional steering would require more room.

The Early Days of Compact Loaders

The concept of this agile loader dates back to the late 1950s. The first versions were developed to meet the needs of farmers who required compact, maneuverable machines for cleaning out barns and handling hay. Traditional tractors were too large for these indoor jobs, and wheelbarrows were too inefficient. The solution was a small, engine-powered machine that could lift material and pivot within its own dimensions.

These early loaders didn’t have the advanced hydraulics or enclosed cabs of modern machines, but they did have the unique ability to steer by skidding their wheels. Operators quickly recognized the advantage: they could maneuver in and out of stalls, corners, and tight alleys without reversing or making wide turns. As the machines evolved, the core feature—the ability to pivot via differential control—remained unchanged.

Why the Name Stuck

Names in the equipment world often reflect either a machine’s function or its mechanism. In this case, the term was directly inspired by how the machine operates. The skidding motion during a turn was so central to the machine’s function that it became the focal point in naming. Over time, the phrase caught on and became the industry standard.

Even as technology advanced and machines grew more powerful, the naming convention remained rooted in its origins. While other loaders may use articulated steering or even four-wheel drive systems with advanced controls, this particular machine is still defined by the way it turns. This clear distinction helps differentiate it from similar-looking equipment that may operate in entirely different ways.

Mechanics Behind the Motion

The method of steering is accomplished through a system of hydrostatic drive motors. These motors are independently powered and allow operators to adjust the speed of each side of the machine using hand or foot controls. When the right side moves forward and the left side remains still—or moves in reverse—the machine pivots.

This pivoting is possible because the loader doesn’t rely on a central axle to change direction. Instead, its movement is dictated by torque distribution and traction differences. While this creates additional stress on tires or tracks during turning, it also allows for a turning radius that is virtually zero. For tasks that require high precision in tight quarters, this design is exceptionally useful.

A Versatile Tool for Many Industries

The practical benefits of this loader go far beyond its turning ability. Its compact size and broad compatibility with attachments make it one of the most adaptable pieces of equipment available. Construction crews, landscapers, farmers, and even utility companies use it for everything from digging and grading to snow removal and demolition.

With the ability to quickly switch between buckets, trenchers, augers, and pallet forks, this machine often eliminates the need for multiple single-function tools. Its ease of use and relatively low maintenance requirements have made it a go-to solution for small contractors and large operations alike.

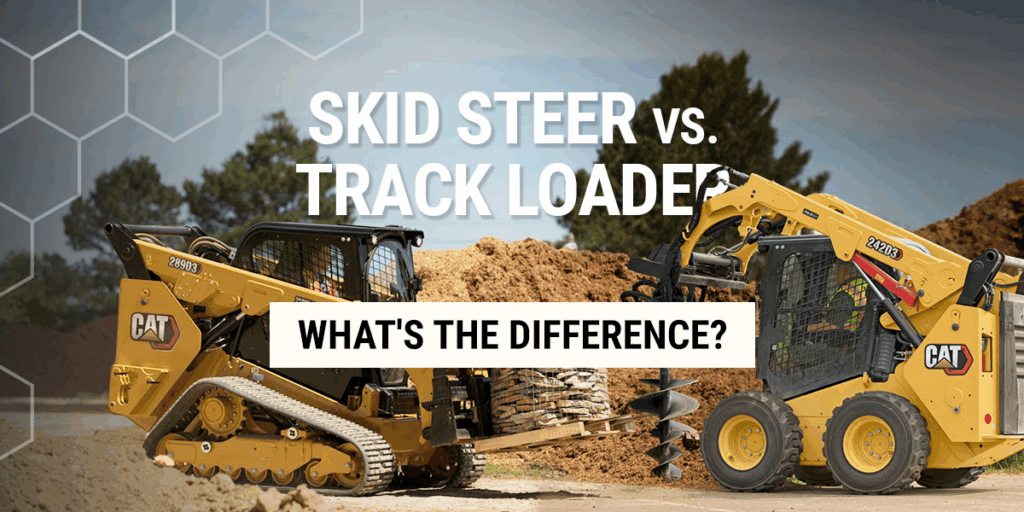

Tracks vs. Wheels

Modern versions of this equipment come in two primary forms: wheeled and tracked. While the wheeled version is the original design, tracked versions—sometimes called compact track loaders—have become increasingly popular. Tracks offer improved traction and stability on loose or muddy ground. They also distribute the machine’s weight more evenly, reducing ground pressure and minimizing damage to turf or soft soil.

Despite these differences, both styles retain the original steering method. Even tracked versions steer by skidding, though the friction behaves differently on various surfaces. On concrete or asphalt, operators often notice a slight jerking motion during sharp turns, a direct result of the same skid-based maneuvering that defines the machine.

Misunderstandings and Myths

Because the name can be misleading to those unfamiliar with the equipment, some assume that “skid” implies a lack of control or stability. In reality, the motion is deliberate and highly controlled. The operator determines the direction and speed of each side of the machine, allowing for precise movement even in tight or cluttered environments.

Another common misconception is that all small loaders are the same. While there are many compact machines on the market, not all use the same steering technique. Some rely on articulation—where the machine bends in the middle—while others may use more conventional automotive-style steering. It’s the unique method of turning that separates this machine from the rest.

Real-World Applications

Whether it’s clearing snow from narrow sidewalks, maneuvering through a barn filled with livestock, or lifting debris on a construction site, this compact loader proves its worth time and again. Its ability to rotate in place means fewer adjustments are needed, saving time and energy. It also reduces the likelihood of damaging property in tight quarters—an important factor in residential and commercial projects alike.

Thanks to its small footprint and powerful lifting capacity, it can be transported easily on trailers and stored without taking up significant space. For businesses that value versatility and efficiency, it’s often the first machine added to the fleet—and the last one retired.

Conclusion

At first glance, the term skid steer might seem like just another bit of technical jargon. But in truth, the name describes the essence of what makes the machine unique: its ability to steer by skidding. This steering method allows for unmatched maneuverability in tight spaces, a feature that has made these machines indispensable across a wide range of industries.

Understanding the origin of the name provides insight into the machine’s design and function. It also highlights why this type of loader has maintained its popularity for decades. Whether you’re operating on a farm, a construction site, or a landscaping project, the compact loader known by this term continues to deliver performance, flexibility, and control—all thanks to a simple, yet highly effective, way of turning.